Master Delivery Windows To Fix Amazon Inbound Logistics

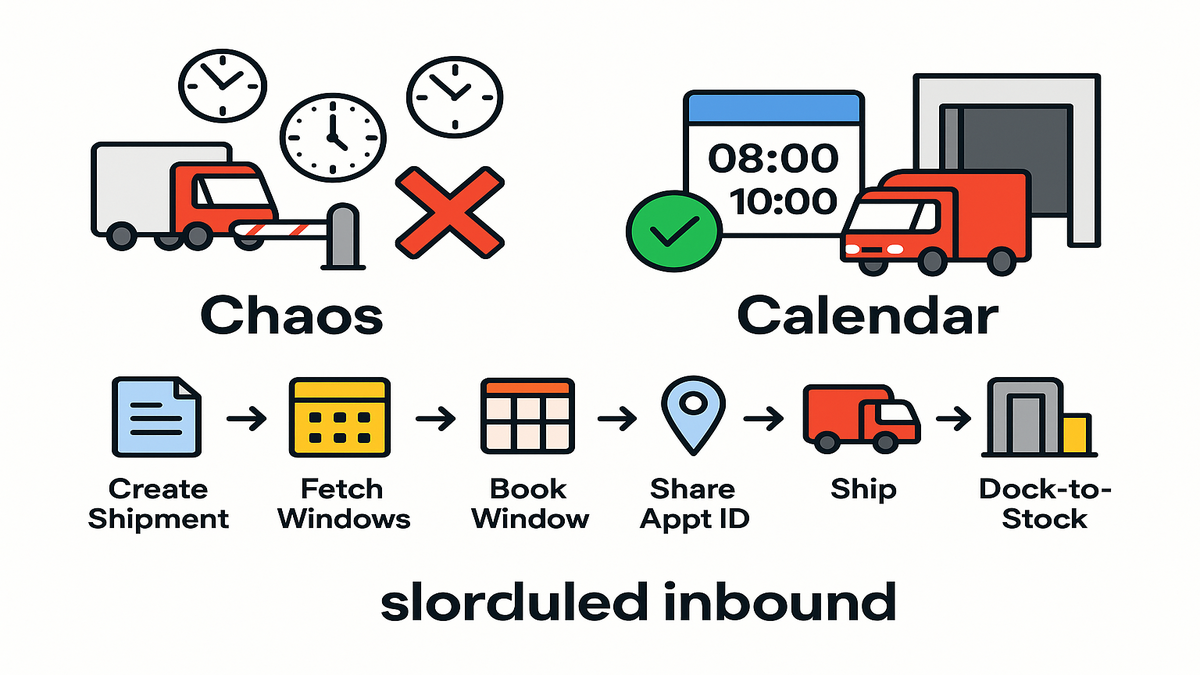

You’re burning money every time a truck shows up unannounced, sits, then gets turned away. That’s not bad luck. That’s a delivery calendar problem.

Here’s the flip: Amazon now lets you view and pick delivery windows via API. Translation: you can book when pallets hit the dock, not just hope. No more guessing carrier timing against FC capacity. Less chaos, faster check-ins, cleaner inventory flow.

If you’ve watched a product launch die because receiving lagged three days, this is for you.

With delivery windows locked, you smooth dock-to-stock times and cut refusals fast. Your IPI looks healthier, and honestly, so does your sanity. You don’t need more trucks. You need a better calendar.

TL;DR

Delivery schedule = the plan for when your inbound hits the dock. Don’t gamble it.

Amazon’s update: view and select delivery windows via API, then book appointments.

Locking windows reduces refusals, detention fees, and painful stockouts.

Build a delivery schedule Excel template and align vendors, carriers, and FCs.

Decode tracking lingo: “local warehouse scheduling delivery” and “delivery rescheduled” mean timing shifts.

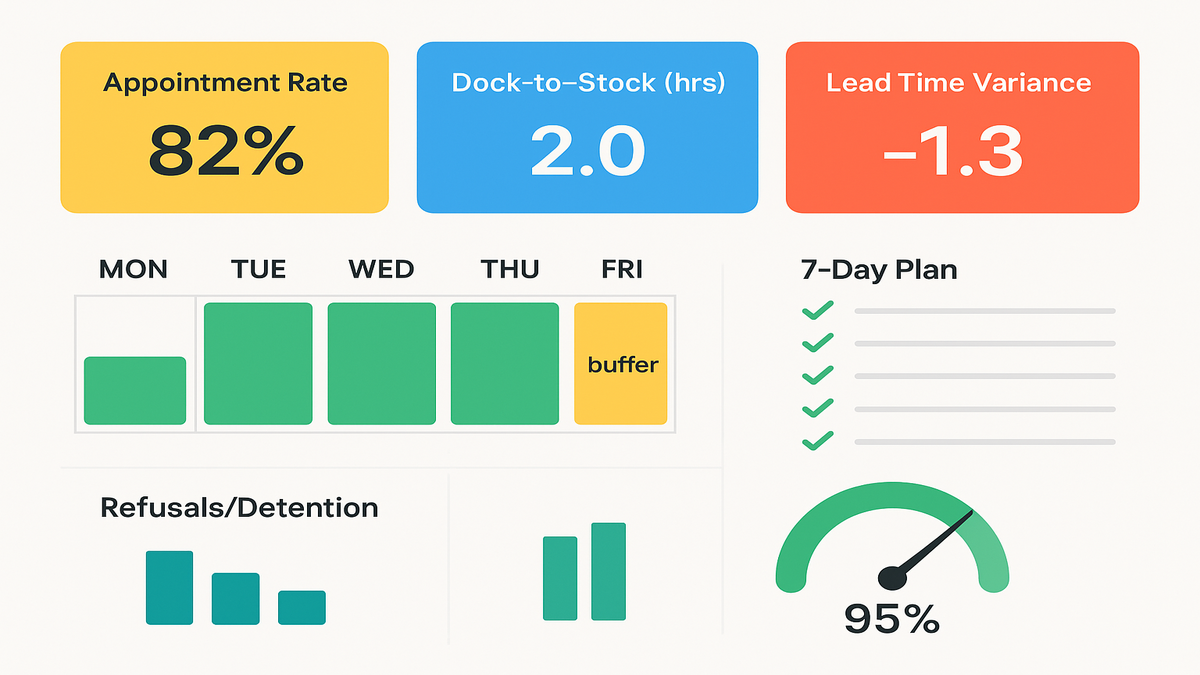

Track KPIs: appointment rate, dock-to-stock, lead time variance, and OOS.

Quick pulse check before we dive in: most inbound “emergencies” aren’t real emergencies. They’re missed appointments, vague ASNs, or trucks sent without a confirmed time. Fix the calendar and the fire drills start to vanish.

Delivery windows decoded

Delivery schedule meaning

A delivery schedule is the who, what, and when of your inbound. Carrier, shipment ID, FC, date and time window, plus any constraints. Big difference between “truck comes sometime Tuesday” and “four pallets 8–10am, door 14, LTL, appointment confirmed.” The first gets refusals and detention. The second gets received units.

In Amazon speak, you can now view and pick delivery windows via API. You’re not guessing dock availability or emailing three people to confirm. You book the appointment, you own the slot.

Think of it like airline boarding versus standby. With a booked window, you’re Group A, straight down the jet bridge. Without it, you’re hoping there’s space after everyone else. That hope costs you in idle trucks and delayed receiving.

Why Amazon inbound windows matter

- FCs run on calendars. If you’re on the calendar, you get dock time. If not, delays.

- Windowed arrivals reduce yard congestion and speed check-in, especially during peak weeks.

- Better predictability boosts in-stock rate and helps protect restock limits and IPI.

If you’re planning promos or scaling paid media when inventory is live, our DSP Services can help you grow reach without fueling stockouts.

First‑hand example: You ship 10 pallets weekly to three FCs. Without appointments, arrivals scatter Tue–Thu and 1–2 get refused monthly. After booking windows, refusals drop to near zero. Dock-to-stock shrinks by a day, and “available to sell” flips faster. No magic. Just scheduling.

Here’s what people forget: FCs have receiving hours, headcount, and door constraints. They prioritize scheduled freight. Unscheduled trucks are easy to bump. Put your load on the calendar and align with how the building actually runs. It’s like showing up with a reservation instead of begging for a table at 7pm.

Pro move: stagger windows across FCs based on demand and geography. Front‑load early-week windows for high-volume ASINs. Use midweek buffer windows to absorb slips. That one change can stabilize on-hand for top sellers during paid pushes.

Plugging into the API

API capabilities

The new capability lets you:

- Pull available delivery windows for a given inbound shipment and FC.

- Select and book a specific time, like Mon 08:00–10:00, for LTL/FTL or eligible consolidations.

- Update or cancel appointments when freight slides.

- Sync appointment IDs and timestamps to your WMS/TMS for one source of truth.

Check the Fulfillment Inbound API reference in Amazon’s SP‑API docs for operations and payloads. Your workflow varies by carrier, partnered or not, and shipment type.

A few implementation notes to save headaches:

- Permissions: make sure your app has the right SP‑API scopes before tests. No scope, no windows.

- Rate limiting: add retries with backoff. Don’t spam the endpoint; queue sensible requests.

- Idempotency: make booking calls idempotent so timeouts don’t create duplicates.

- Source of truth: store the appointment ID in the shipment record and on the BOL. That one field cuts dock arguing by 90%.

A simple workflow blueprint

- Create or prepare the FBA shipment in your system.

- Call the API to fetch available windows for the destination FC.

- Book the best window using transit time and carrier capacity.

- Push appointment details to your carrier and vendor.

- Print labels and BOLs with the appointment ID.

- Monitor check-in; if transit slips, rebook before the window.

First‑hand example: You’re shipping 6 pallets LTL from New Jersey to ABE8. Transit is 1.5 days, so you pull Friday morning windows. You book 9–11am, push the appointment ID to the carrier, and the driver references it on arrival. Receiving scans match your ASN; units turn available next day. Snowstorm delays pickup, so you cancel and rebook Monday. No fees, no refusals.

Advanced tips the pros use:

- Buffer math: take P95 transit, add 6–8 hours for terminals, then book the earliest window after that. Fast, but still real.

- Calendar sync: generate an ICS invite per appointment and drop it into a shared Ops calendar.

- Alerting: set Slack or Teams alerts for “appointment booked,” “arrived,” and “missed.” Rebook fast when something slips.

Edge cases to expect, and how to handle them:

- Mixed-mode shipments: if part of a PO is SPD and part LTL, treat them as separate calendar items.

- Holiday and peak weeks: windows are tighter. Book earlier and favor FCs with faster dock-to-stock for must-have SKUs.

- Partnered vs. non-partnered carriers: flows differ, but the appointment ID still ties everything together.

From chaos to calendar

Delivery schedule example

- Monday: 8–10am, FC A, 4 pallets (replen high sellers)

- Tuesday: 1–3pm, FC B, 2 pallets (slow movers + long-tail)

- Wednesday: 8–10am, FC C, 6 pallets (promo and seasonal)

- Thursday: Buffer window for rebooks or urgent PO fill

- Friday: No inbound (reserve for cross-dock or carrier overflow)

Each line has a shipment ID, appointment ID, carrier, and ASN count. Vendors get cutoff times tied to these windows. Carriers get pickup SLAs backsolved from the dock appointment. Your ops scoreboard shows appointment rate at 95% or better.

Why this works: you turn demand planning into time on a dock. Marketing knows when inventory clears. Finance sees fewer surprise fees. Support sees fewer “Where is my order?” tickets because sellable dates are predictable.

Delivery schedule template

Create columns for: Shipment ID, FC, Carrier, Mode (SP/LTL/FTL), Pallets or Cartons, Appointment Window, Appointment ID, Transit ETA, Pickup Date, ASN Complete, Status, Notes.

- Use data validation for FC codes and modes.

- Color‑code bookable windows versus tentative.

- Add a “late risk” formula: if Transit ETA + 6 hours > Appointment Start, flag red.

Two reminders: packages should be organized properly, labeling and pallets are tight, BOL has the appointment ID. Your ASNs must be accurate. Most delays start with sloppy prep.

First‑hand example: A brand runs this template plus API integration. Every Friday, they schedule next week’s windows, send vendor cutoffs, and lock pickups with carriers. Missed windows fall from 4 per month to 0–1, and detention goes away.

If you want to push beyond Excel:

- Hook the sheet to an App Script that pings the API, writes confirmed windows, and emails vendors the weekly plan.

- Build a one-click rebook button that opens your booking page pre-filled.

- Archive weekly tabs to audit misses and spot patterns by FC, carrier, or weekday.

Common pitfalls, with fixes:

- Pitfall: Labels don’t match ASNs, so receiving puts you on hold. Fix: scan-verify labels against ASN before pickup.

- Pitfall: Pickup cutoffs unclear, carrier misses the window. Fix: send a weekly one-pager with pickup SLA and appointment IDs.

- Pitfall: Overloading one FC while others sit empty. Fix: rebalance windows using last week’s dock-to-stock as your guide.

Quick pit stop

- Appointments turn yard chaos into clockwork. Book early and rebook fast if timing slips.

- A simple Excel schedule can run your inbound calendar until you automate.

- Align vendor cutoffs and carrier pickups to your dock window, not the other way.

- Monitor appointment rate, dock-to-stock, and lead time variance every week.

Add one more to your mental shortlist: protect high-velocity ASINs with the earliest, firmest windows. Everything else can flex around them.

Tracking talk

Shein local warehouse meaning

If you see “local warehouse scheduling delivery,” the parcel reached a regional facility. Next step is coordinating delivery or handoff to the last‑mile carrier. In plain terms: the package is nearby, and a delivery day is being aligned. It’s the DTC cousin of booking an inbound dock window, same concept.

Caveat: wording varies by market and carrier. Always cross-check the Shein timeline and the carrier’s status page for the best ETA.

Delivery rescheduled meaning

“Delivery rescheduled” means the promised arrival date moved a bit. Weather, capacity, address issues, or missorts are common reasons. Carriers usually update to the next business day. UPS and FedEx show a new “Scheduled Delivery” date. USPS may show “In Transit, Arriving Late.” It’s a timing slip, not doom.

Pro tip: When you’re the shipper, tell customers the moment status changes. Clear comms can turn a 1‑star into a patient wait.

First‑hand example: A seller mapped “rescheduled” events to support macros. Auto‑emails cut “Where is my order?” tickets by about 30% during storms.

If you want to automate the calm:

- Connect carrier webhooks to your helpdesk.

- Trigger a message when status flips to “rescheduled” or “exception.”

- Include the new ETA, a short sorry, and what to do if late past X date.

KPIs and ROI

KPIs you should track

- Appointment rate: percent of inbound shipments with confirmed windows before pickup.

- Lead time variance: difference between planned and actual transit-to-dock time.

- Dock-to-stock time: hours from FC arrival to units available.

- Refusal and detention incidents: count and cost per month.

- In‑stock rate on top sellers: keep 95% or better during promos.

Track these weekly. If dock-to-stock creeps up or refusals rise, audit by FC and mode. Then shift windows or carriers where it hurts.

How to define and use them:

- Appointment rate = Booked appointments / Total inbound shipments. Target above 95%. Low rate means guessing.

- Lead time variance = Actual transit days − Planned transit days. Keep variance small. Big swings mean lane issues.

- Dock-to-stock = Time from first FC scan to units available. Use rolling averages to spot bottlenecks.

- Refusal and detention incidents = Count and dollars. If dollars climb, fix upstream booking, not just argue fees.

- In-stock rate on top sellers = Days in-stock / Total days. Anchor their windows early.

Why this pays off

- Lower soft costs: fewer yard holds and fewer reships.

- Less revenue swings: predictable conversion since replenishment lands when marketing says.

- Better IPI posture: faster sell‑through and clean inbound protect restock limits.

First‑hand example: A home goods brand moved to appointment-first inbound. They centralized booking in ops and tied it to weekly S&OP. They paused promos unless inventory had booked windows. Result: fewer stockouts during ads and a clean Q4, no extra headcount.

A quick ROI sketch to share upstairs:

- Baseline: 4 refusals per month at $250 detention, plus one extra dock-to-stock day on 10 pallets. That’s $1,000 in fees plus lost sales.

- After scheduling: refusals drop to 0–1, dock-to-stock down 24 hours. If your top ASIN sells 100 units a day at $20 contribution, that recovered day is $2,000. Net: the calendar paid for itself in week one.

FAQs

- Q: What’s the fastest way to start if I don’t have engineers?

A: Start with a delivery schedule Excel template and a weekly booking ritual. Many 3PLs or freight partners can book for you. Document preferred windows and SLAs first.

- Q: Do I still need appointments for small parcel (SPD)?

A: Policies vary by FC and volume. LTL and FTL almost always need appointments. For SPD and consolidations, match pickup timing to receiving hours and follow prep rules.

- Q: How early should I book my inbound delivery window?

A: As soon as you know transit timing. Ideally when you create the shipment and confirm pickup. If lead times swing, book conservative, then rebook if you speed up.

- Q: What if my carrier misses the window?

A: Rebook right away via API or portal. Log the miss, share root cause, and add buffer next time. Chronic misses? Switch carriers or change pickup days.

- Q: Does “delivery rescheduled” mean the package is lost?

A: No. It means the ETA moved. Check the next scan, look for a new date, and communicate early.

- Q: How do I keep ASNs and labels from causing delays?

A: Validate ASNs before pickup. Put appointment IDs on BOLs. Ensure cartons and pallets match labels. The fastest inbound scans clean on the first try.

- Q: Bonus Q: Who should own the calendar internally?

A: One person. Centralize booking and rebooking in Ops, but make it visible to Planning, Marketing, and Support through a shared dashboard or calendar feed.

Your first 7 days

- Day 1: Build the delivery schedule Excel template with the columns above.

- Day 2: List weekly FC targets and define preferred windows by day.

- Day 3: Loop in vendors and carriers and set pickup cutoffs.

- Day 4: Connect to SP‑API, or assign your 3PL, to pull and book windows.

- Day 5: Book next week’s appointments and put IDs on labels and BOLs.

- Day 6: Ship, monitor scans, and rebook if transit slips.

- Day 7: Review KPIs like appointment rate and dock-to-stock, then adjust windows.

You don’t need a huge tech stack to win here. You need a calendar, a cadence, and a habit of booking early.

If you only take one thing: scheduling inbound is an operations cheat code. The API didn’t invent good logistics. It just made them easier to do every time. Your job is to lock windows, align partners, and keep the loop tight. Do that, and inventory stops being a fire and becomes a flywheel.

“Delivery windows aren’t red tape—they’re runway. Put freight on a schedule, and sales start landing on time.”

Want to see how top brands operationalize this? Explore our Case Studies.

References

- Amazon Selling Partner API documentation:

- Fulfillment Inbound API v0 reference:

- Amazon Inventory Performance Index overview:

- FedEx Tracking support and status help:

- UPS Tracking Support (status definitions and help):

- USPS Tracking help center:

- FBA prep and labeling basics (public overview):

- CSCMP Supply Chain Glossary (definitions like dock-to-stock):